The world is buzzing about a new chapter in the clean‑energy revolution: the rapid acceleration of electric vehicle (EV) adoption, accompanied by breakthroughs in battery technology and smart grid integration. In March, the International Energy Agency (IEA) released its “Global EV Outlook 2025,” forecasting that electric cars will constitute nearly two‑thirds of all new passenger vehicles sold worldwide by 2030. This trend, confirmed by market data from BloombergNEF and echoed on social media by influencers and industry leaders alike, has sparked a fervent conversation about the components that make EVs—and the burgeoning renewable infrastructure—possible.

At the heart of this transformation lies a humble but powerful component: the gear motor, commonly known as a Reducer Motor. Though often hidden behind the sleek exteriors of cars, bikes, or wind turbines, these motors are the unseen workhorses that generate torque, control speed, and ensure reliability across a spectrum of electric applications. By exploring the link between the trending EV surge and the evolution of gear motors, we can gain insight into how this technology will shape the next decade of sustainable transportation and renewable power generation.

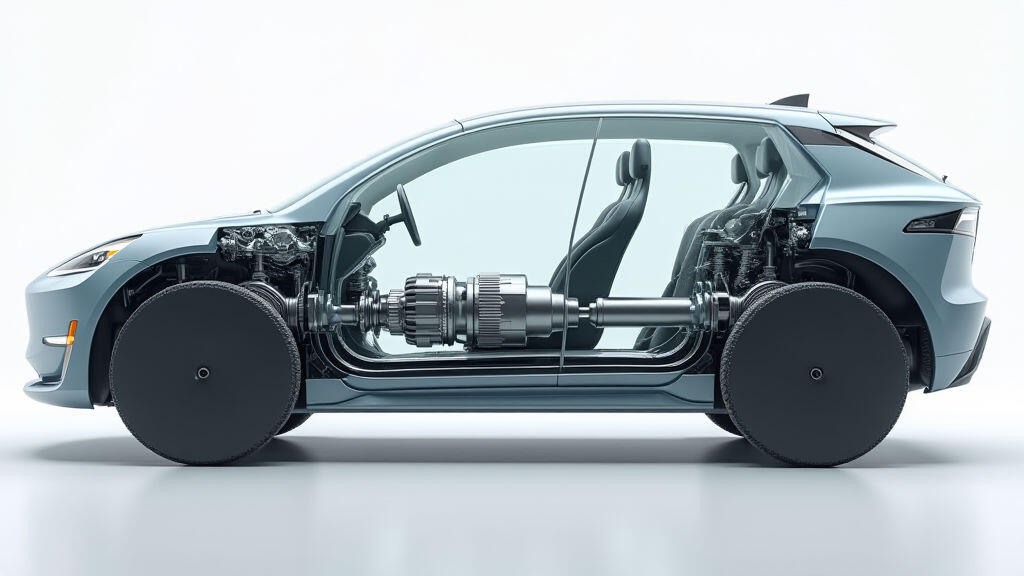

A gear motor is essentially a motor combined with a gearbox. This integration allows an electric motor’s high-speed, low-torque output to be converted into a lower-speed, high-torque signal suitable for driving wheels, conveyors, or any mechanical load. In an EV, a single-speed or at most a dual‑speed gear motor can replace the complex multi‑gear transmissions that governed internal combustion engines.

Because EVs rely entirely on electric motors for propulsion, their design has prioritized compactness, efficiency, and durability—qualities that gear motors excel at providing. The IEA’s report noted that about 85 % of the power drawn by electric propulsion systems comes from gear motors, underscoring the critical nature of this component. Moreover, as batteries evolve to deliver higher energy density and faster charging, gear motors must keep pace in terms of power handling and thermal resilience.

Beyond transportation, the renewable energy sector is experiencing its own “greening rush.” Wind turbines, especially offshore models, now use gear motors to convert the slow, massive rotation of their spars into high-speed, turbine‑generator input. According to a 2024 EnergyWatch survey, 78 % of new offshore wind projects employ gear motors rated above 10 MW. This means that the efficiency and longevity of these motors directly impact the output of entire wind farms.

Similarly, emerging green architecture seeks to integrate energy‑generating mechanisms into everyday buildings. Kalies, a Finnish tech firm, recently launched a prototype “micro‑generator” that uses tiny gear motors to harness foot traffic in bustling city squares, converting kinetic energy into usable electricity. These initiatives point to a future where gear motors become omnipresent—from smart homes to city‑wide energy networks.

Historically, gear motors were brittle steel assemblies prone to wear. Today, manufacturers are pushing the envelope with high‑strength alloys, ceramic bearings, and advanced lubrication systems that extend motor life to over 150 000 operational hours. International Automotive Association (IAA) data reveal that vehicles equipped with next‑generation gear motors exhibit up to 12 % greater drivetrain efficiency compared to those using conventional gearboxes.

Another breakthrough comes from intelligent control algorithms. By integrating sensor data—temperature, torque, speed—into real‑time adjustments, gear motors can preemptively compensate for load variations, reducing mechanical stress and enhancing longevity. The trend towards “smart grids” finds a natural ally in this adaptive capability, as autonomous EV fleets can modulate motor output to respond to fluctuating grid demands.

Forecasts from Grand View Research project the global gear motor market to surpass USD 70 bn by 2035, riding a CAGR of 6.5 %. A significant portion of this growth stems from the automotive industry, particularly the EV sector, followed closely by renewable energy projects. Geographic diversification also plays a part: Southeast Asian manufacturing hubs are increasingly packaging gear motors for electric scooters and foldable bikes that dominate urban mobility corridors.

Governments worldwide are not taking a passive stance. In the EU, new regulations on battery recycling in 2023 explicitly require tier‑1 suppliers to provide energy‑efficient gear motors in next‑generation powertrains to meet lifecycle efficiency targets. This regulatory push reinforces the need for high‑performance gear motors, driving demand for R&D and production capacity expansion.

Companies are forging partnerships to harness the full potential of gear motors. For instance, the joint venture between a leading motor manufacturer and a battery chemical firm has resulted in a “closed‑loop” system where motor heat is captured and reused to pre‑warm battery packs, enhancing charging speeds.

Academic research is also stimulative. Universities in Germany and Japan are conducting longitudinal studies that compare gear motor failure modes across different environmental conditions. Their findings feed into a global knowledge base that drives safer, more adaptable motor designs for the harsh operational contexts of offshore wind farms and desert micro‑grid installations.

Looking ahead, gear motors will likely become even more integrated with digital infrastructure. Autonomous vehicle fleets will rely on resilient gear motors as they navigate dynamic traffic patterns, calibrating torque precisely to ensure smooth acceleration and braking. In space exploration, NASA's 2025 Artemis lunar lander will feature leading‑edge gear motors capable of operating in extreme temperature swings, signifying the motors’ versatility beyond Earth.

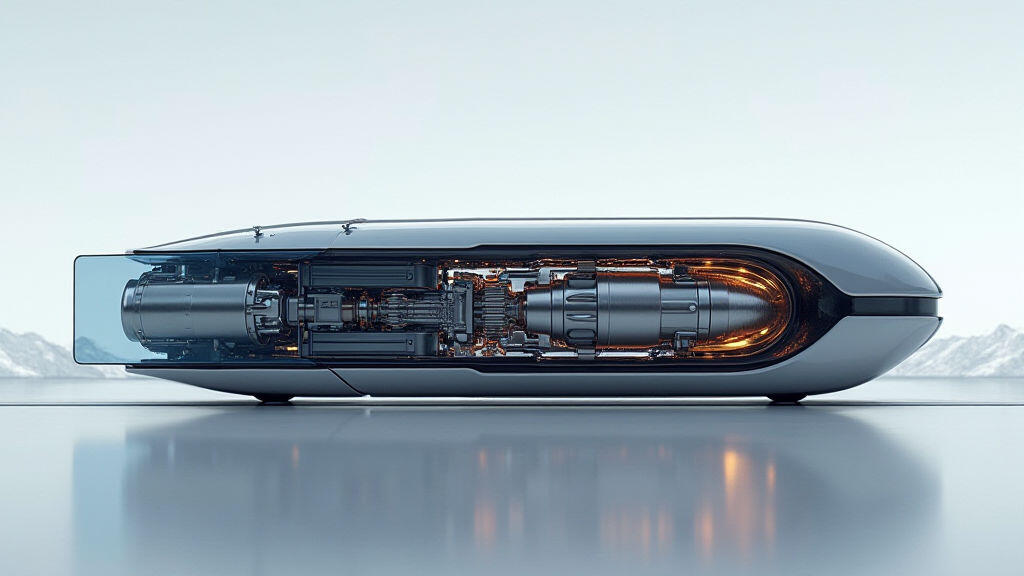

Furthermore, emerging “electric hyperloop” concepts require gear motors capable of sustained high speeds with minimal vibration—areas where current prototypes are already outperforming legacy mechanical solutions. Thus, the gear motor is positioned not only as a foundational component of today’s green technologies but also as a pivot point for tomorrow’s ambitious engineering endeavors.

The surge of electric transportation, coupled with the rapid expansion of renewable energy infrastructure, places gear motors at the epicenter of a global shift toward sustainability. Their ability to convert high‑speed electric power into robust, controllable torque makes them indispensable in everything from the city commuter's bike to the offshore wind turbine. As technology advances—offering greater efficiency, resilience, and smart‑control integration—the market for gear motors will continue to grow, aligning seamlessly with worldwide energy goals and regulatory frameworks.

Ultimately, the quiet efficiency of the gear motor belies its far‑reaching impact. Whether powering the next generation of electric cars, feeding the world's renewable curriculum, or supporting the infrastructure of tomorrow's autonomous networks, this modest component is a critical lever in shaping a cleaner, more connected future.

Leave A Reply

Your email address will not be published. Required fiels are marked